Questo è poi solitamente seguito da 4-6 passaggi di diamanti legati in resina e poi l'applicazione di un sigillante

Tempo di rilascio:

2022-05-17

Il calcestruzzo lucidato è ottenuto applicando una serie di passaggi meccanici di rettifica e levigatura utilizzando attrezzature, indurenti chimici e sigillanti per creare una superficie esteticamente gradevole

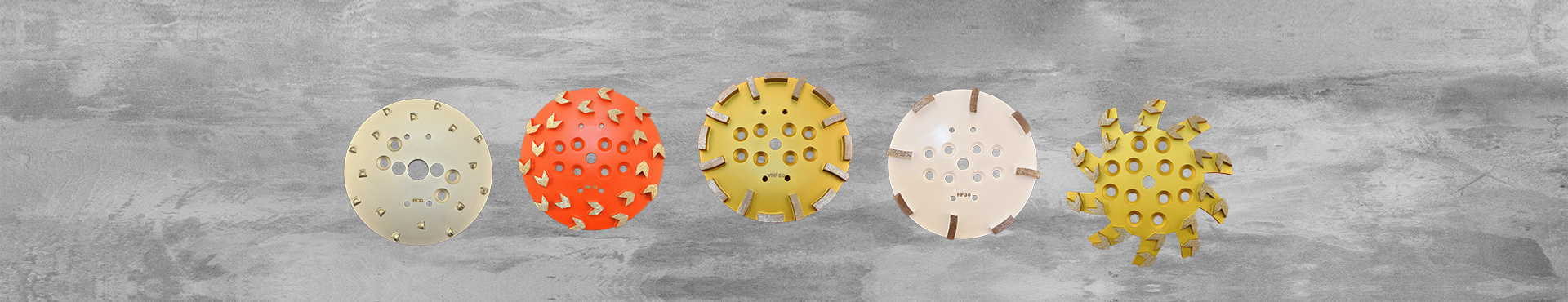

Polished concrete is achieved through applying a series of mechanical grinding and honing steps using equipment, chemical hardeners and sealers to create a surface that is aesthetically pleasing, durable and easily maintained. Depending on the desired effect and finish of the floor surface a Polishing project usually consists of up to 3 steps of metal bonded diamond shoes, conjunctionally with a Densifier & Hardner. This is then usually followed by 4-6 steps of resin bonded diamonds and then the application of a sealer. Polished floors take significantly more time and effort to produce a high-end finish. Concrete Polishing is more suited for a more high-end result. Usually, you would see Polished Concrete floors in Car showrooms, Property showroom, Hotel Lobbies or Bank Lobbies.

Benefits of Concrete Polishing

- High-end result

- Improved reflection & ambient light

- Improved GreenStar Rating

- Easy to clean

- Eliminates Dusting

- Reduces Tire Marks

- Reduces or Eliminates ASR (Alkali Silicate Reaction)

Maintenance

Unlike a grind and seal project, Polished concrete requires more maintenance to maintain that super reflective surface. Usually, it requires an application of C2 Cleaners designed for maintenance, that is concrete neutral to ensure your floors stay shiny for longer.

INFORMAZIONI CORRELATE